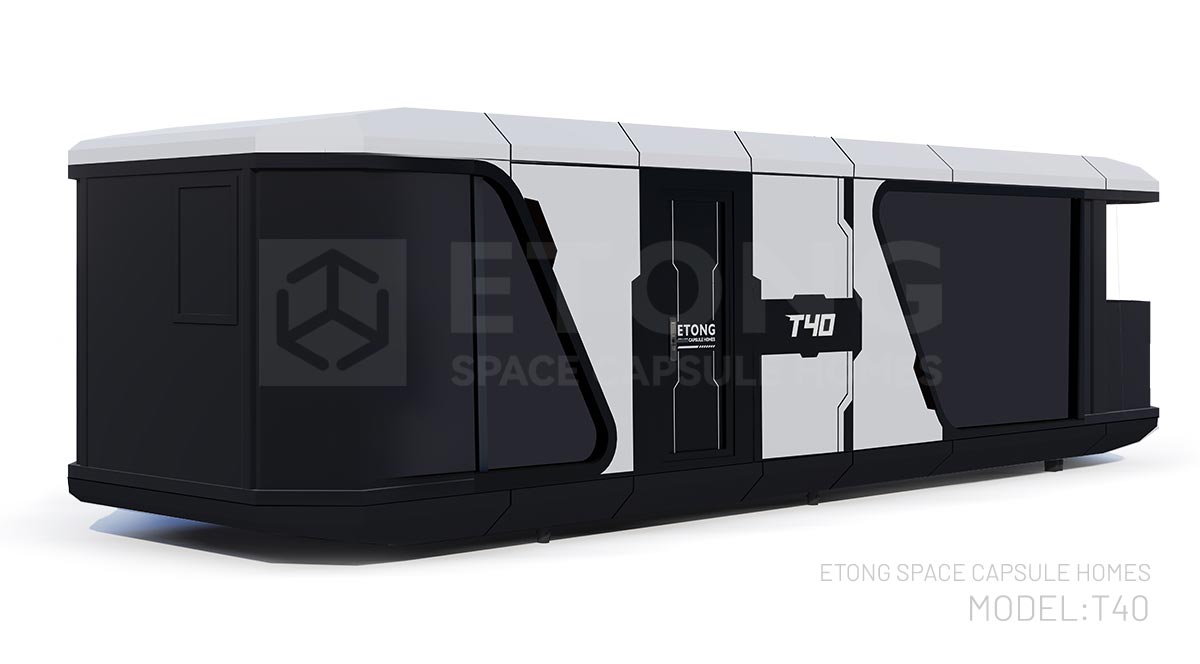

ETONG T40 38m² Aluminum Alloy Mobile Prefabricated Home

1.The 38m² aviation-grade aluminum alloy prefabricated structure incorporates ergonomic spatial planning, supporting multifunctional living configurations for seamless integration of living and entertainment functions.

2.Featuring a customizable modular design, the mobile space capsule home enables user-defined functional zoning and dimensional scalability to meet tailored operational needs.

3.Engineered with acoustic insulation systems and environmental monitoring capabilities, the mobile space capsule home provides enhanced privacy protection compared to centralized residential complexes.

Introduction to 38m² Aerospace-Grade Aluminum Mobile Prefabricated Structure

Modular building systems, also referred to as demountable engineered structures, represent a transformative construction methodology. These aviation-grade aluminum alloy solutions redefine traditional building practices through precision-engineered modules that enable rapid deployment and relocation. This industrial innovation signifies a paradigm shift in architectural philosophy, transitioning future construction sites from dust-intensive operations to clean-room assembly environments. The structural installation process utilizes factory-produced modular units, fundamentally transforming industry workflows through industrialized precision manufacturing.

Specifications of 38m² Aluminum alloy mobile prefabricated house:

| Appearance | With balcony |

| Dimensions | 11500mm X 3300mm X3200mm |

| Floor area | 38 ㎡ |

| Number of users | 2-4 |

| Power consumption | 11KW |

| Weight | 10.5T |

Advantages of Mobile Prefabricated Homes

Mobile prefabricated homes are transportable structures manufactured off-site and delivered to installation locations, with modern units primarily deployed as permanent residential solutions.

Standard configurations include sleeping areas, window systems, and integrated appliances. Compliance with international transport regulations requires collapsible sidewall systems (sliding/folding mechanisms) to reduce width during transit, while some designs use modular assemblies requiring on-site reconstruction.

While traditional deployment involves leased plots in dedicated communities with centralized utilities, current installations increasingly occupy private land. The structure supports both permanent foundation mounting and temporary stabilization via ground anchors or tension-based systems.

Featuring military-grade durability and extended service life, mobile prefabricated homes offer 40-60% cost efficiency over conventional construction. Rapid deployment (≤72-hour assembly) includes integrated utilities (water/power/gas infrastructure). The modular design ensures 92% material reusability across redeployment cycles, with near-zero construction waste when disassembling undamaged components.